At first glance, handmade tea is very intimidating. In Wazuka, hand-picked and hand-rolled tea are the most expensive senchas in Japan. Because of its high price, only the masters are allowed to touch the tea during this process.

Nevertheless, you can make your own handmade tea at Obubu, and it is actually quite simple. Whether it tasting good or not is a different matter, but it is still a great opportunity to learn and get a chance to feel the tea at your own pace throughout the entire processing period.

One of the teas I tried to make was oolong tea. Oolong is very interesting because anything from 20% to 80% oxidation is generally considered an oolong. Lighter oxidized oolongs are generally more floral, while darker oolongs are richer and earthy.

To create my oolong, I first picked my tea leaves. When picking green tea, the usual practice is to pick two leaves and one bud. However, for oolongs, you can pick even the third or fourth leaf down. This is because an oolong tea will get a lot of its taste from the oxidation process, rather than from the freshness of the leaves.

Next I let my leaves to sun dry. This stresses the leaves and leads to reactions within the tea leaf that help produce the oolong’s aroma.

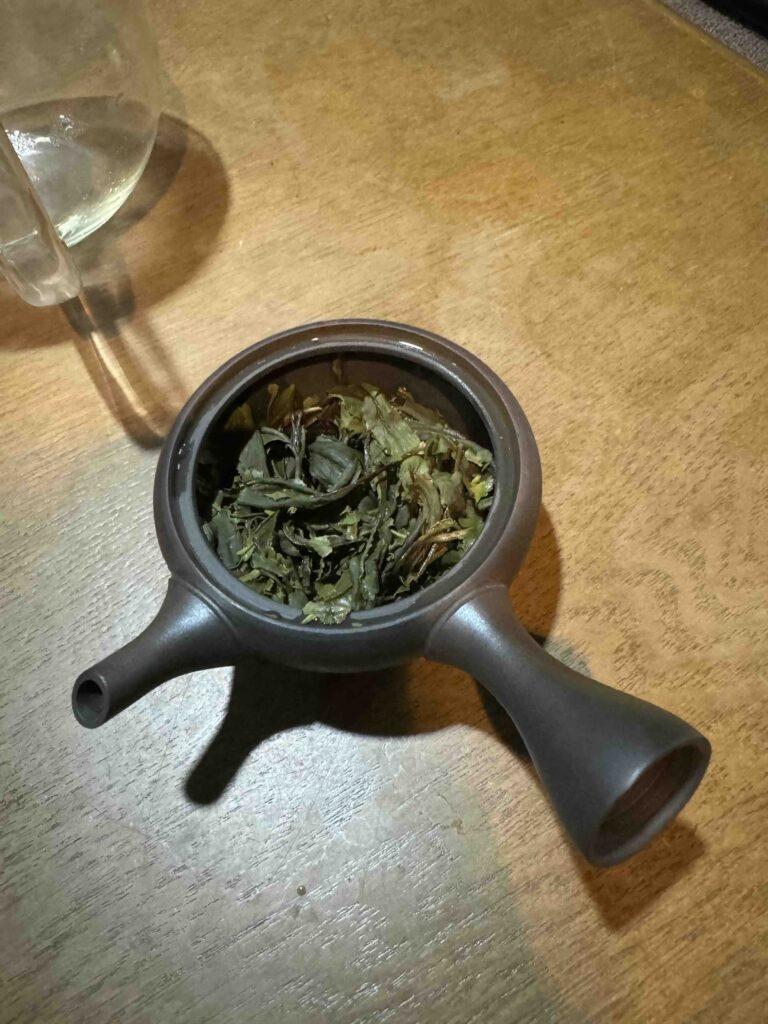

The third step is to bruise my tea leaves. I do this by tossing my leaves in a small basket. This helps to encourage the oxidation process. This causes the outer rim of the leaf to brown while the core of the leaf stays green. This is a key to oolong tea. If the entire leaf has browned, then it is a black tea.

The fourth step is to stop the oxidation process. Oxidation is generally best stopped through heat. In green tea, this is done during the steaming stage. For my oolong tea, I stopped it through pan frying.

The fifth step is to roll. Rolling helps break down the cell walls of the tea leaf. Since I don’t have a machine to roll for me, I did this by putting my leaves into a cloth and trying to roll it into a ball.

Finally all I have to do is dry the leaves. In order to imitate drying in a furnace, I instead use an oven set to around 96 C and I let my leaves dry until it snaps when I bend it. This makes the leaves shelf stable and I can share my experiment with everyone else!

While there were many steps in making this oolong, none of the steps were challenging enough that I ruined my batch of tea. In the end, I was still able to produce a floral, lightly oxidized oolong tea!

Here are some memorable reactions from my fellow interns:

“Well it isn’t the worst tea I ever had!”

“It has a little bit of an astringent aftertaste but overall it’s not bad!”

“I can drink a second brew of this”

– Nathan, Intern #169